- English

- 简体中文

- Esperanto

- Afrikaans

- Català

- שפה עברית

- Cymraeg

- Galego

- 繁体中文

- Latviešu

- icelandic

- ייִדיש

- беларускі

- Hrvatski

- Kreyòl ayisyen

- Shqiptar

- Malti

- lugha ya Kiswahili

- አማርኛ

- Bosanski

- Frysk

- ភាសាខ្មែរ

- ქართული

- ગુજરાતી

- Hausa

- Кыргыз тили

- ಕನ್ನಡ

- Corsa

- Kurdî

- മലയാളം

- Maori

- Монгол хэл

- Hmong

- IsiXhosa

- Zulu

- Punjabi

- پښتو

- Chichewa

- Samoa

- Sesotho

- සිංහල

- Gàidhlig

- Cebuano

- Somali

- Тоҷикӣ

- O'zbek

- Hawaiian

- سنڌي

- Shinra

- Հայերեն

- Igbo

- Sundanese

- Lëtzebuergesch

- Malagasy

- Yoruba

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

- Umshini Wokugcwalisa

- Izinsiza Ezisekelayo Ekugcwaliseni Umugqa Wokukhiqiza

- Isistimu Yokudlulisa Izinto

- Umshini Wokugcwalisa Uketshezi Wamakhemikhali

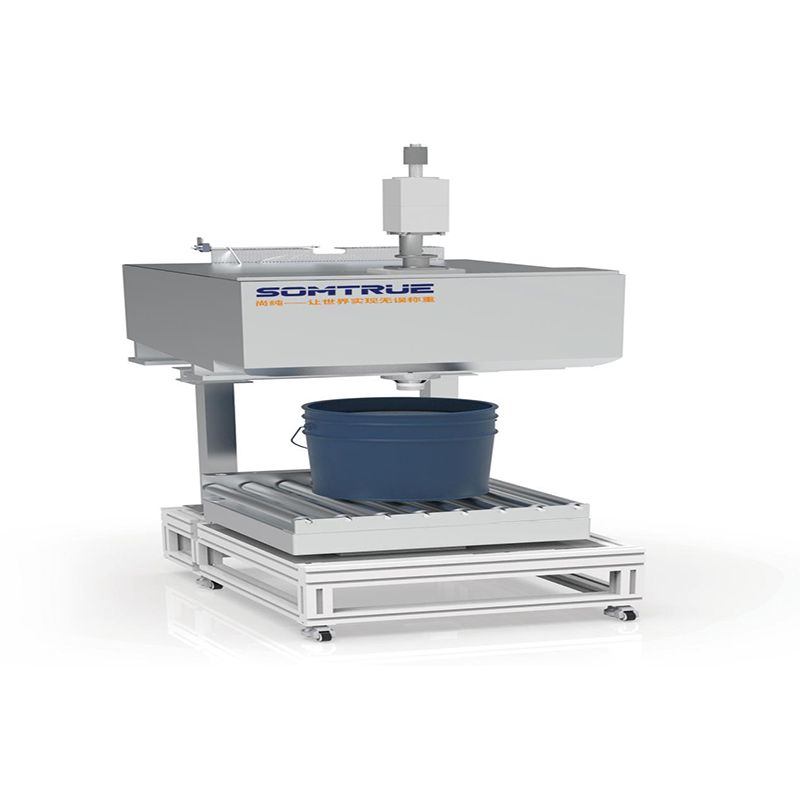

- Umshini Wokugcwalisa Ibhakede Elincane Le-Chemical Liquid

- Umshini Wokugcwalisa I-Chemical Liquid Omkhulu Wokugcwalisa Imigqomo

- I-Chemical Raw Material Yokugcwalisa Imiphongolo Encane

- Umshini Wokugcwalisa Imiphongolo Ye-Chemical Raw Material

- Umshini Wokugcwalisa Amabhakede Okwengeza Amakhemikhali Amancane

- Umshini Wokugcwalisa Umgqomo Omkhulu Wekhemikhali

- Umshini Wokugcwalisa Uketshezi Lwempahla Eyingozi

- Umshini Omusha Wokugcwalisa Uketshezi Lwamandla

- Umshini Wokugcwalisa Uketshezi Lwebhethri ye-Lithium

- Umshini Omkhulu Wokugcwalisa Uketshezi Lwemigqomo

- Umshini Wokugcwalisa Uketshezi Lwemithi

- Umshini Wokugcwalisa I-Resin Liquid

- Umshini Wokugcwalisa Upende Nokwemboza

- Umshini Wokugcwalisa Amakhemikhali

20L Tank Semi-Automatic Impahla Eyingozi Liquid Umshini Wokugcwalisa

Ifanele umshini oyingozi wokugcwalisa uketshezi. Ukugeleza kwenqubo: Ngemva kokuba umgqomo ongenalutho ususendaweni, ukugcwaliswa kwesilinganiso esikhulu sokugeleza kuqala. Lapho umthamo wokugcwalisa ufinyelela umthamo ohlosiwe wokugcwalisa ama-coarse, izinga lokugeleza elikhulu livaliwe, futhi ukugcwaliswa kwesilinganiso sokugeleza okuncane kuqala. Ngemuva kokufinyelela inani elihlosiwe lokugcwalisa kahle, umzimba we-valve uvaliwe ngesikhathi.

Thumela Uphenyo

Ukugeleza Kwenqubo:

Ifanele umshini oyingozi wokugcwalisa uketshezi. Ukugeleza kwenqubo: Ngemva kokuba umgqomo ongenalutho ususendaweni, ukugcwaliswa kwesilinganiso sokugeleza okukhulu kuyaqala. Lapho umthamo wokugcwalisa ufinyelela umthamo ohlosiwe wokugcwalisa ama-coarse, izinga lokugeleza elikhulu livaliwe, futhi ukugcwaliswa kwesilinganiso sokugeleza okuncane kuqala. Ngemuva kokufinyelela inani elihlosiwe lokugcwalisa kahle, umzimba we-valve uvaliwe ngesikhathi.

Ingxenye yokuhlanza ye-valve yokugcwalisa kanye nepayipi yokugcwalisa ingahlakazwa futhi ihlanzwe, elula futhi elula.

Amapharamitha Abalulekile Wezobuchwepheshe:

|

Isiteshi sokugcwalisa |

isiteshi esisodwa; |

|

Incazelo yomsebenzi |

ipuleti lokuconsa ekhanda lesibhamu; Ngaphansi komshini wokugcwalisa unikezwa nge-tray liquid ukuvimbela ukuchichima; |

|

Amandla okukhiqiza |

cishe imiphongolo engu-80-120 ngehora (imitha engu-20L; Ngokusho kwe-viscosity yezinto zekhasimende nezinto ezingenayo); |

|

Iphutha lokugcwalisa |

≤±0.1%F.S; |

|

Izinto ezigelezayo |

304 insimbi engagqwali; |

|

Okubalulekile |

carbon steel spray plastic; |

|

Ukuvala impahla ye-gasket |

I-PTFE; |

|

Indinganiso yesixhumi esibonakalayo |

ikhasimende elinikeziwe; |

|

Usayizi wekhanda lesibhamu |

I-DN40 (ehambisanayo ngokosayizi wesixhumi esibonakalayo sekhasimende) |

|

Ukunikezwa kwamandla kagesi |

I-AC220V/50Hz; 0.5 kW |

|

Umthombo womoya odingekayo |

0.6 MPa; |

|

Indawo yokusebenza umswakama ohlobene |

< 95% RH (akukho ukujiya); |

Isithombe sempahla yokupakisha: