- English

- 简体中文

- Esperanto

- Afrikaans

- Català

- שפה עברית

- Cymraeg

- Galego

- 繁体中文

- Latviešu

- icelandic

- ייִדיש

- беларускі

- Hrvatski

- Kreyòl ayisyen

- Shqiptar

- Malti

- lugha ya Kiswahili

- አማርኛ

- Bosanski

- Frysk

- ភាសាខ្មែរ

- ქართული

- ગુજરાતી

- Hausa

- Кыргыз тили

- ಕನ್ನಡ

- Corsa

- Kurdî

- മലയാളം

- Maori

- Монгол хэл

- Hmong

- IsiXhosa

- Zulu

- Punjabi

- پښتو

- Chichewa

- Samoa

- Sesotho

- සිංහල

- Gàidhlig

- Cebuano

- Somali

- Тоҷикӣ

- O'zbek

- Hawaiian

- سنڌي

- Shinra

- Հայերեն

- Igbo

- Sundanese

- Lëtzebuergesch

- Malagasy

- Yoruba

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

- Umshini Wokugcwalisa

- Izinsiza Ezisekelayo Ekugcwaliseni Umugqa Wokukhiqiza

- Isistimu Yokudlulisa Izinto

- Umshini Wokugcwalisa Uketshezi Wamakhemikhali

- Umshini Wokugcwalisa Ibhakede Elincane Le-Chemical Liquid

- Umshini Wokugcwalisa I-Chemical Liquid Omkhulu Wokugcwalisa Imigqomo

- I-Chemical Raw Material Yokugcwalisa Imiphongolo Encane

- Umshini Wokugcwalisa Imiphongolo Ye-Chemical Raw Material

- Umshini Wokugcwalisa Amabhakede Okwengeza Amakhemikhali Amancane

- Umshini Wokugcwalisa Umgqomo Omkhulu Wekhemikhali

- Umshini Wokugcwalisa Uketshezi Lwempahla Eyingozi

- Umshini Omusha Wokugcwalisa Uketshezi Lwamandla

- Umshini Wokugcwalisa Uketshezi Lwebhethri ye-Lithium

- Umshini Omkhulu Wokugcwalisa Uketshezi Lwemigqomo

- Umshini Wokugcwalisa Uketshezi Lwemithi

- Umshini Wokugcwalisa I-Resin Liquid

- Umshini Wokugcwalisa Upende Nokwemboza

- Umshini Wokugcwalisa Amakhemikhali

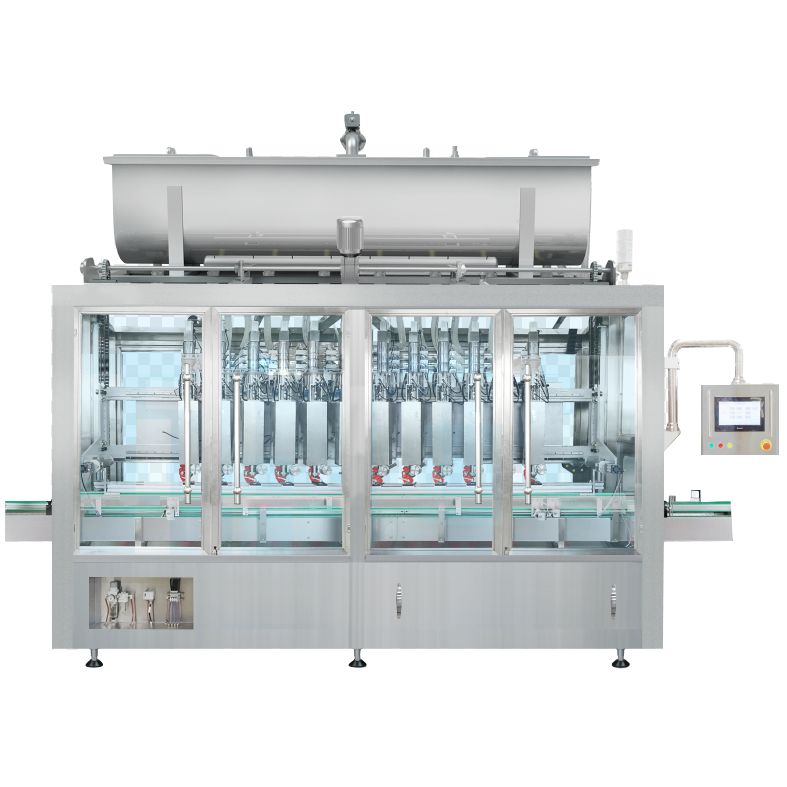

I-5L Barrel Automatic Chemical Raw Filling Machine

Ingxenye yokugcwalisa yomshini ibona ukugcwalisa ngokushesha nokugcwalisa kancane nge-cylinder ye-throttle kabili. Ekuqaleni kokugcwalisa, ngemva kokuba isilinda esiphindwe kabili se-throttle siguqulelwe ku-stroke 1, siguqulwa ngokushesha sibe yi-stroke 2 ukuze sigcwaliswe ngokushesha. Ngemuva kokugcwalisa inani elibekiwe lokugcwalisa ngokushesha, isilinda esingaphansi kwamanzi sikhuphukela emlonyeni womgqomo, futhi isilinda esiphindwe kabili se-throttle siguqulwa sibe yi-stroke 1 ukuze siqhubeke nokugcwalisa kancane kuze kufinyelelwe inani eliphelele lokugcwalisa elibekiwe.

Thumela Uphenyo

Ukugeleza Kwenqubo:

Ingxenye yokugcwalisa yomshini ibona ukugcwalisa ngokushesha nokugcwalisa kancane nge-cylinder ye-throttle kabili. Ekuqaleni kokugcwalisa, ngemva kokuba isilinda esiphindwe kabili se-throttle siguqulelwe ku-stroke 1, siguqulwa ngokushesha sibe yi-stroke 2 ukuze sigcwaliswe ngokushesha. Ngemuva kokugcwalisa inani elibekiwe lokugcwalisa ngokushesha, isilinda esingaphansi kwamanzi sikhuphukela emlonyeni womgqomo, futhi isilinda esiphindwe kabili se-throttle siguqulwa sibe yi-stroke 1 ukuze siqhubeke nokugcwalisa kancane kuze kufinyelelwe inani eliphelele lokugcwalisa elibekiwe.

Iwumshini ofanele wokupakisha wemboni yamakhemikhali emihle.

1. Umshini wamukela isilawuli esihlelekayo (PLC) kanye nesikrini sokuthinta sokulawula ukusebenza, okulula ukusisebenzisa nokulungisa.

2. Kukhona uhlelo lokukala kanye nempendulo ngaphansi kwekhanda ngalinye lokugcwalisa, elingasetha inani lokugcwalisa lekhanda ngalinye futhi lenze ukulungiswa okukodwa okuncane.

3. Izinzwa, ama-proximity switches, njll. zonke ziyizingxenye zokuzwa ezithuthukisiwe, ukuze kungabikho bhakede elingagcwaliswa, futhi i-barrel blocking master izoma ngokuzenzakalelayo bese i-alamu.

4. Inhloko yokugcwalisa inomsebenzi wokugcwalisa ama-coarse futhi omuhle ukuqinisekisa isivinini sokugcwalisa nokunemba. Inhloko yokugcwalisa ifakwe idivayisi yokondla, engakwazi ukubamba izinto ezintantayo ngemuva kokuba ikhanda lokugcwalisa livaliwe, ukuze impahla yekhanda lokugcwalisa ingawisi emgqonyeni, ikhanda lokugcwalisa lingawi, futhi isiteshi sokugcwalisa igcinwe ihlanzekile. Isibhamu sonke sekhanda lokugcwalisa kufanele sihanjiswe phezulu naphansi ngokuzenzakalelayo futhi silungiswe ngokuvundlile, futhi isibhamu se-spray kufanele sinwetshwe emgqonyeni ngesikhathi sokugcwalisa ukuvimbela ukuphuma lapho izinto zincane, futhi ukugcwaliswa kungafinyelela i-zero drip.

5. Izinto ezisetshenziswayo zinedivayisi yokuguqula ukusebenza kwamaphuzu okwenziwa ngesandla kanye ne-othomathikhi, ekwazi ukubona ukugcwaliswa kwamamitha okuzimele kwebhakede elilodwa; Imishini inomsebenzi wokulawula ijubane okwenziwa ngesandla kanye ne-othomathikhi. Akukho ukuchitheka kukawoyela lapho ukuhanjiswa kuqala.

Amapharamitha Abalulekile Wezobuchwepheshe:

|

Inani lamakhanda okugcwalisa |

2 |

|

Okubalulekile |

carbon steel spray |

|

Ukugcwalisa usayizi wesibhamu |

I-DN50 |

|

Iphutha lokulinganisa |

20L±20mL |

|

Ukunikezwa kwamandla kagesi |

I-AC380V/50Hz; 3.0 kW |

|

Umfutho womthombo womoya |

0.6 MPa |